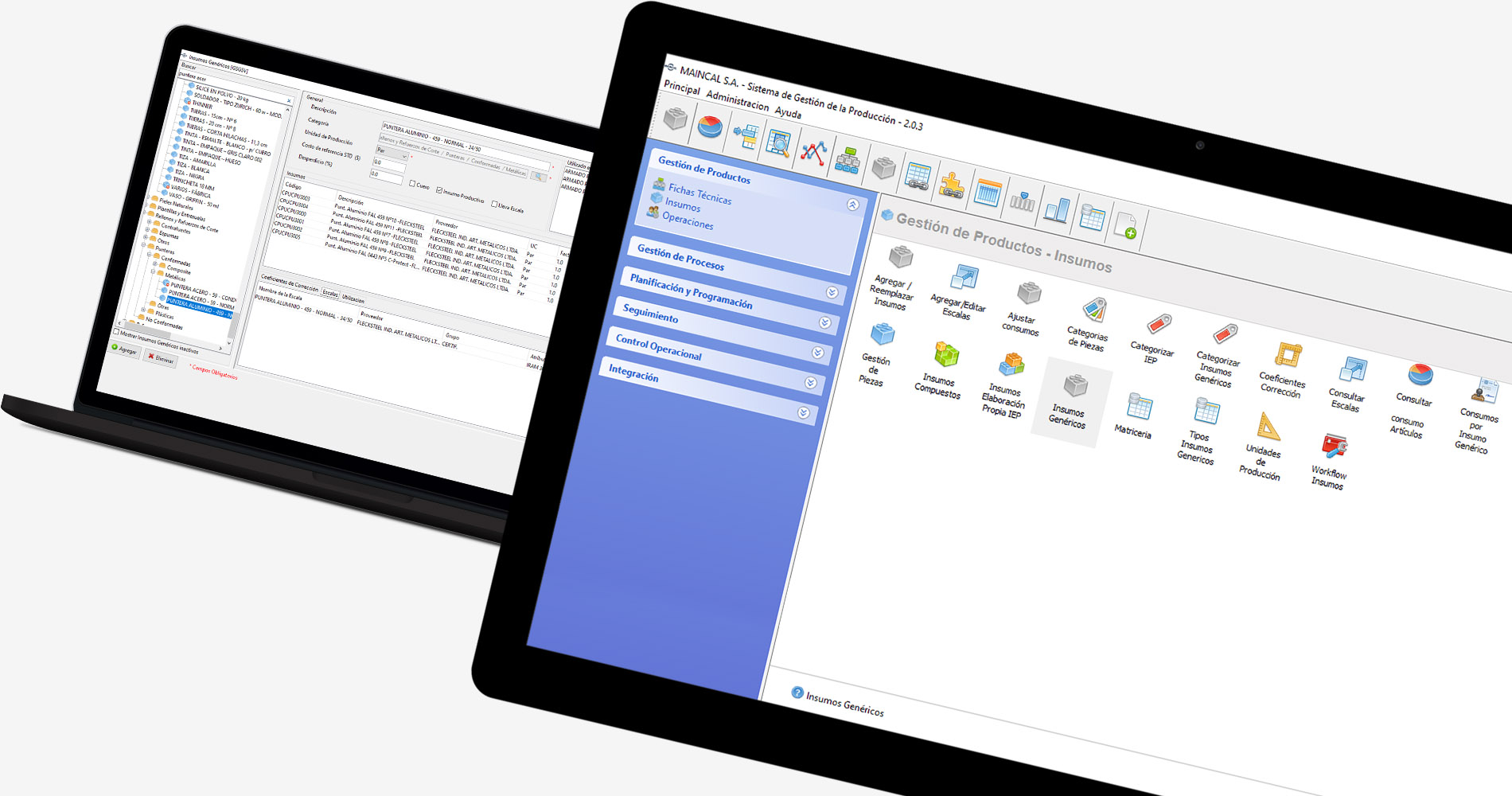

Innovative solutions to the industrial dynamics of manufacturing.

Along with Maincal S.A. we design creative solutions to the integral management of its manufacturing processes. We've been technologically enhancing their most ambitious projects for many years.

Each year, it produces more than 800,000 units aimed at major companies, security forces and other government agencies.

We managed to implement an organization transversal system, fully integrated, robust and flexible capable of adapting to the continous an changing productive dynamic.

The complexity of the production process, together with the organizational dynamics of the company, demanded great efforts and commitment from the work team, also made up by representatives of the company.

Currently, this system is a fundamental piece to the productive organizationof the company.

With over 200 screens and dozens of concurrent users.

Main benefits and key achievements of our development